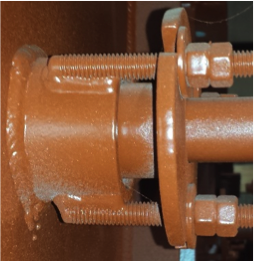

Flextech can include most types of actuation requirements, i.e. electric, pneumatic, manual, etc…, as well as accommodate other requirements such as an extended shaft or mounting of a customer supplied device.

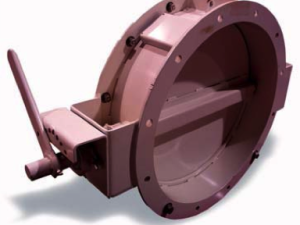

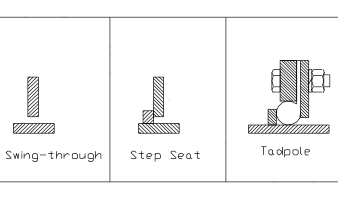

Our line of Butterfly dampers are available for a wide variety of applications in round ducting where low leakage, flow control, or a combination of the two are required. Flow characteristics are similar to that of a single blade Louver Damper design and can be supplied in varying degrees of shutoff (90 to 99.9%) depending on the specific applications and seal arrangement. Design components include rolled plate steel frame with plate steel or rolled angle flanges, plate steel blade (stiffened A/R), and round bar shafts (stub and full length).